Valves

Valves are mechanical devices that controls the flow and pressure within a system or process. They are essential components of a piping system that conveys liquids, gases, vapors, slurries etc.. Different types of valves are available: gate, globe, plug, ball, butterfly, check, diaphragm, pinch, pressure relief, control valves etc. Each of these types has a number of models, each with different features and functional capabilities. Some valves are self-operated while others manually or with an actuator or pneumatic or hydraulic is operated.

BUTTERFLY VALVE DN 100A JIS 5K CAST IRON WAFER TYPE

Butterfly valves are among the family of quarter-turn valves and work very similar to ball valves. The “butterfly” is a disk connected to a rod. It closes when the rod rotates the disc by a quarter turn to a position perpendicular to the flow direction. When the valve opens, the disk is rotated back to allow the flow.

Butterfly valves are used for on-off or modulating services and are popular due to their light weight, small installation footprint, lower costs, quick operation and availability in very large sizes. These valves can be operated by handles, gears or automatic actuators.

GLOBE VALVE DN 40A JIS 5K BRONZE JIS F. 7301

Globe valves are extensively employed to control flow. The range of flow control, pressure drop, and duty must be considered in the design of the valve to avert premature failure and to assure satisfactory service. Valves subjected to high-differential pressure-throttling service require specially designed valve trim.

Generally the maximum differential pressure across the valve disc should not exceed 20 percent of the maximum upstream pressure or 200 psi (1380 kPa), whichever is less. Valves with special trim may be designed for applications exceeding these differential pressure limits.

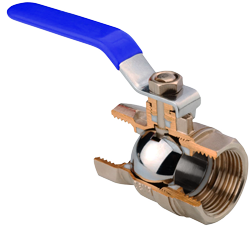

BALL VALVE DN 25A 10K BRONZE

A ball valve is a shut off valve that controls the flow of a liquid or gas by means of a rotary ball having a bore. By rotating the ball a quarter turn (90 degrees) around its axis, the medium can flow through or is blocked. They are characterized by a long service life and provide a reliable sealing over the life span, even when the valve is not in use for a long time. As a result, they are more popular as a shut off valve then for example the gate valve.

Moreover, they are more resistant against contaminated media than most other types of valves. In special versions, ball valves are also used as a control valve. This application is less common due to the relatively limited accuracy of controlling the flow rate in comparison with other types of control valves. However, the ball valve also offers some advantages here. For example, the valve still ensures a reliable sealing, even in the case of dirty media.

CONTROL VALVE JIS 10K ON/OFF 2.5”

Control valves are valves used to control conditions such as flow, pressure, temperature, and liquid level by fully or partially opening or closing in response to signals received from controllers that compare a “setpoint” to a “process variable” whose value is provided by sensors that monitor changes in such conditions

The opening or closing of control valves is usually done automatically by electrical, hydraulic or pneumatic actuators. Positioners are used to control the opening or closing of the actuator based on electric, or pneumatic signals.

QUICK CLOSING VALVE BODY C.S JIS 5K

Quick closing valve is a kind of pressure reducing valve in which the an automatic process control valve for fluid pressure control is used for unmanned machinery spaces. This can be done by careful selection of valve trim, i.e. the parts of the valve that come in contact with the controlled fluid and form an actual control portion. The difference between pressure release valve and quick closing valve is that the later does not come in direct contact with the fluid it is controlling.